With new strains introducing unique challenges in the fight against coronavirus, the demand for efficient and reliable COVID-19 test kits that can be used in the home has become increasingly amplified. Recently, medical device producers have reached out urgently to leading medical contract manufacturing companies for their help in overcoming many of the obstacles that were present in making these kits widely available. This is why, with decades of experience in comparable diagnostic test kit manufacturing, Micron was well prepared to rise to the challenge when a global medical equipment producer approached the team seeking the guidance and capabilities that needed to get their COVID-19 home test kit to market.

Manufacturing Partnerships Accelerate Test Kit Production

As a medical and diagnostic test kit manufacturer producing hundreds of thousands of single-use kits used in medical or veterinary diagnostic applications every year, our team at Micron was well prepared to apply our depth of experience in manufacturing single-use medical components to help overcome the nationwide challenges of the COVID-19 pandemic.

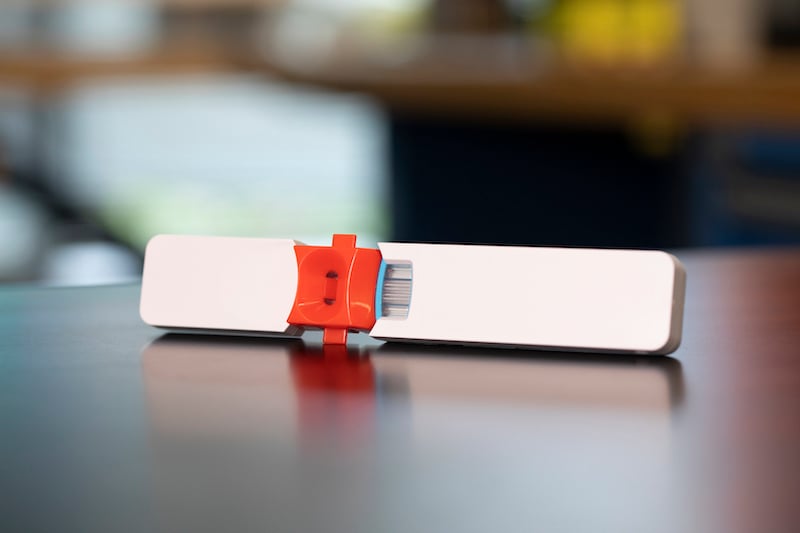

Extensive DFM, molding, and manufacturing experience was applied to help optimize the test kits for manufacturability by focusing on simplicity. The home test kit’s design is similar to a diabetic test kit where a person can check their daily glucose levels, relying on a serology test that would indicate both the presence of antibodies and COVID positivity or negativity.

Strict Regulatory Compliance In Medical Test Kit Production

Since the team at Micron already had the expertise of producing widely-used testing and diagnostic kits in the medical and veterinary industries, the same manufacturing capabilities and strategies were ready to be applied to produce the COVID-19 home test kits with rapid implementation. Producing medical kits relies on following strict compliance standards, detailed documentation, and consistent production methods. The Current Good Manufacturing Processes (cGMP) for pharmaceutical quality and the ISO 13485 requirements were already in place, governing the facilities and processes where the kits would be produced.

Injection molding, assembly, and packaging took place in specialized clean rooms to ensure no contamination would impact the quality of the kits, which included specialty packaging and barcoding for easy traceability, and contained all the items a consumer would require to execute the test at home:

- Lancet to perform the needle prick

- Blood reservoir to collect the few droplets of blood

- Alcohol wipe

- Bandage

- Barcoded pouch to hold the entire kit

- Return pouch with matching barcoding to hold the blood sample for testing

Micron’s in-depth expertise in this field resulted in a high-quality product that will allow people to test themselves for COVID antibodies in their own home and determine if medical care would be necessary, eventually leading to a reduced burden on medical facilities during times when cases surge.

If you are a medical test kit producer seeking a contract manufacturer with the medical injection molding experience to help you refine and grow your product line, Micron is ready to help. Contact Micron today for more information.