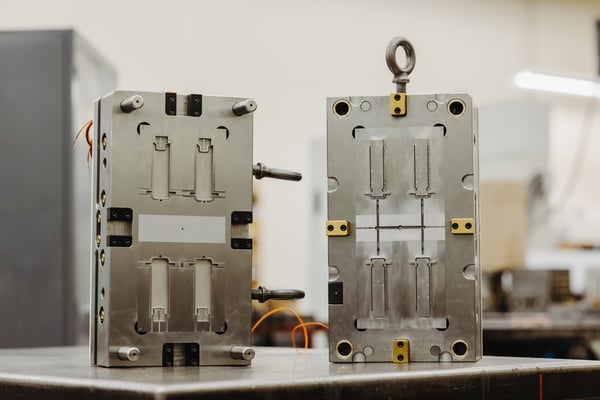

Injection Molding Single-Use Laboratory Plastics Manufactured Under Strictly Regulated Conditions

As life science companies continue to push boundaries in terms of product development, Micron can offer both the expertise and capital to excel in projects ranging in scale and complexity. Our team of mold makers, plastics engineers, process engineers, project engineers, and quality engineers are dedicated to ensuring predictable production of high-quality molded labware at high volumes.

Micron is an ISO 13485 registered & cGMP 21 CFR part 820 compliant facility with Class 7, 8, or 10 cleanrooms and dry-rooms for production and assembly services. Our team is experienced in a variety of engineered resins and is ready to meet your needs, no matter the challenge.

Our life science customers rely on Micron's plastic injection molding services for a wide array of disposable labware, including:

- Petri dishes and lids

- Pipettes

- Test tubes

- Microplates

- Beakers

- Flasks

- Scintillation vials

- Surgical instruments

- Cryovials

For over 30 years, Micron has been a leading custom plastic injection molding manufacturer for companies developing and commercializing single-use medical devices, pharmaceuticals, laboratory equipment, diagnostic test kits, and many other products that require custom-designed or unique plastic labware in a range of sizes and shapes. We excel in meeting tight deadlines while maintaining the highest quality standards in the industry.