If you need a plastic part molded with extreme precision—for example, to ensure there’s no air leak between two molded sections or to be certain there’s no visible seal gap line—you likely require precision molding. The difference between a typical injection molded part and a precision molded part is the tolerance, or acceptable range of variation in dimension: While the majority of injection molded parts have a tolerance of +/- .005″, precision molding holds tolerances between +/- .002″ and +/- .001″ (or less, in some cases).

Precision Molding: Three Questions That Could Save You Money

Manufacturing Single-Use Products: 7 Things To Keep In Mind

A single-use product is meant to be used or applied once and then discarded. The term “single-use” is sometimes intended to mean “disposable,” though this isn’t always the case. A bullet and a booster rocket, for example, are both single-use products—but most people wouldn’t refer to them as a disposable. But many medical products, like tongue depressors and test vials, are perfect examples of single-use, disposable products.

3 Common Types Of Rapid Tooling Used In Prototyping

Rapid tooling is, simply, the creation of a mold in a shortened timeline.

Rapid tooling got its start in the 1990s, when engineers involved in injection molding wanted to see if they could build molds in a matter of hour or days instead of the weeks or months a machined mold would take. A rapid-tooled mold is ideal for prototyping a part and molding a few hundred plastic parts before full-scale, high-volume production starts.

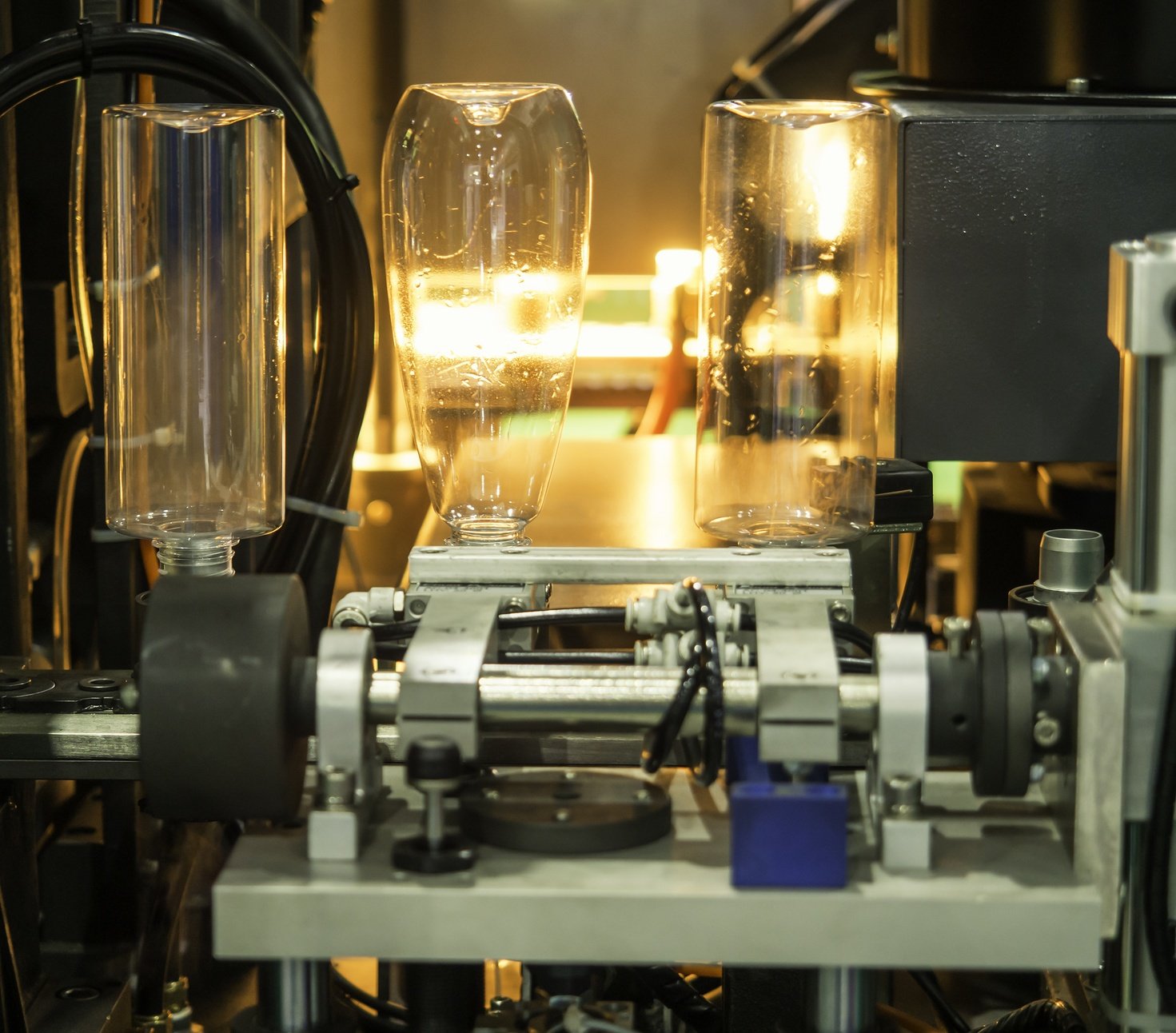

Blow Molding Vs. Injection Molding: A Comparison For Engineers

Blow molding vs. injection molding—what’s the difference? Both are common methods used to create plastic parts. And while some parts require both blow-molded and injection-molded components—for example, a medical device with a blow-molded container attached to an injection molded apparatus, or a military application with a blow-molded “payload” packet fabricated inside an injection molded projectile—the two methods primarily serve different markets.

What Type Of Molding Process Does Your Prototype Require?

If you’re creating a plastic part, it’s important to know what type of injection molding process your part will require. Do you know if your part needs to be molded in a cleanroom environment, or whether you should use a vertical or horizontal injection molding machine?

Plastic Mold Manufacturing: A Behind-The-Scenes Look At Micron

There are thousands of plastic injection molding companies around the world, but here at Micron, we like to think we approach things a little differently from the rest of the crowd.

One of those differences is that we do our plastic mold manufacturing in-house as opposed to outsourcing this job. This allows us a high degree of quality control throughout the mold-making process, and helps to address any questions or issues on an injection molding project before the mold is created.

Cleanroom Molding: What You Need To Know Before Manufacturing

If you need to manufacture a plastic part that must remain as clean as possible—like an implantable medical device—you'll need to have your part made in a cleanroom environment.

Cleanroom molding is the process of creating plastic parts in a special room optimized to reduce the risk of contamination by dust or other particles. The medical, pharmaceutical, aerospace, military, and biotech industries frequently require parts to be created in a cleanroom environment.

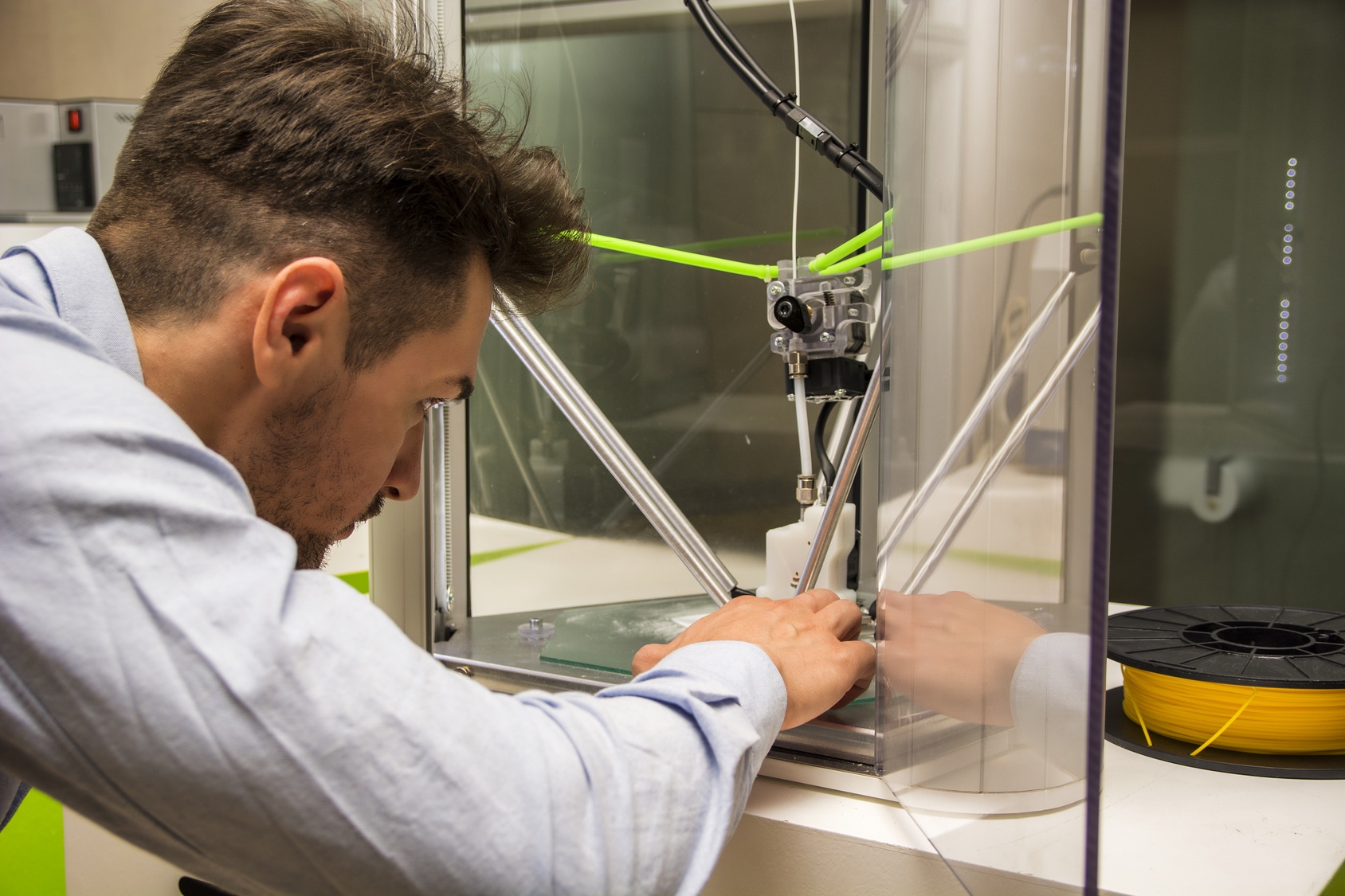

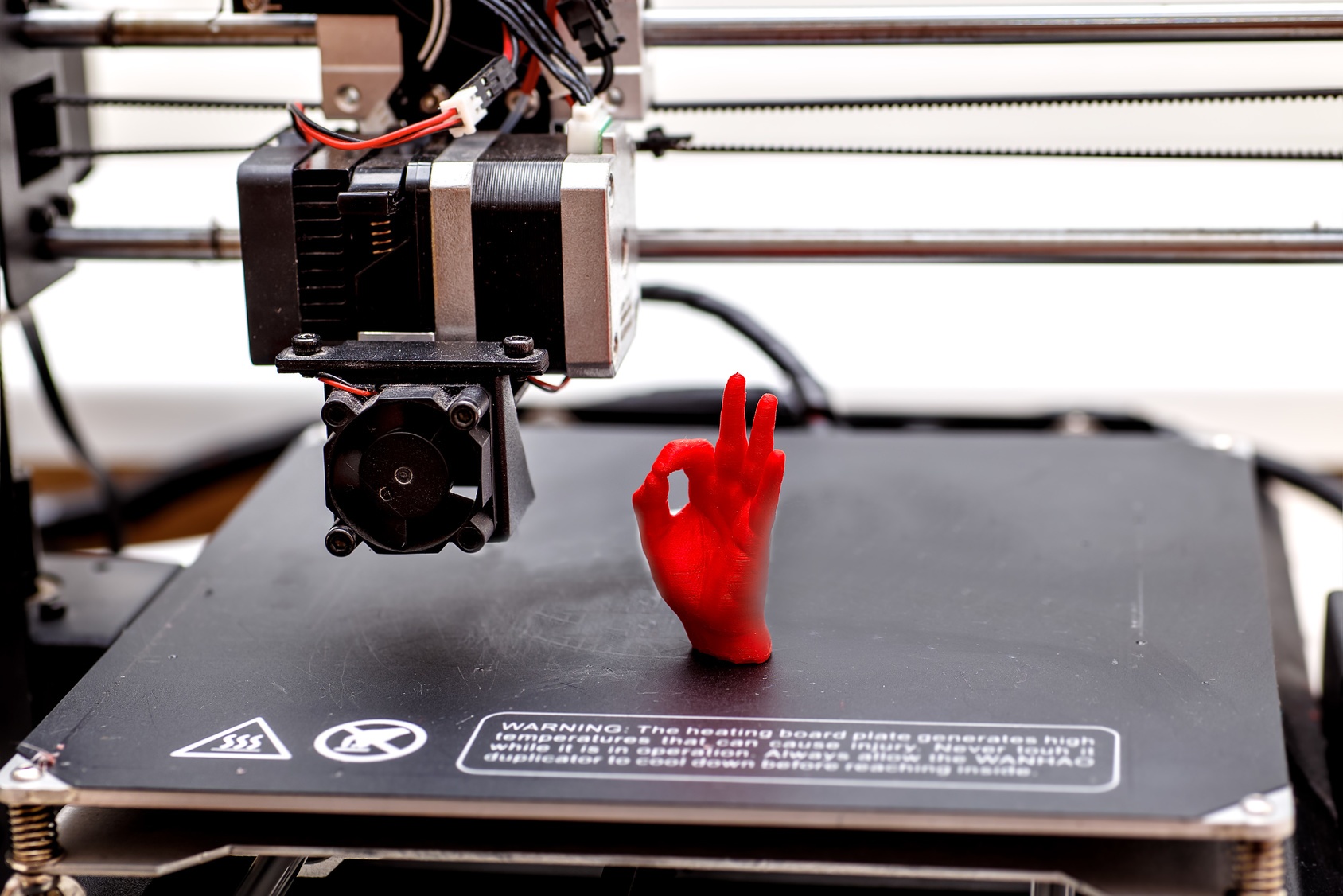

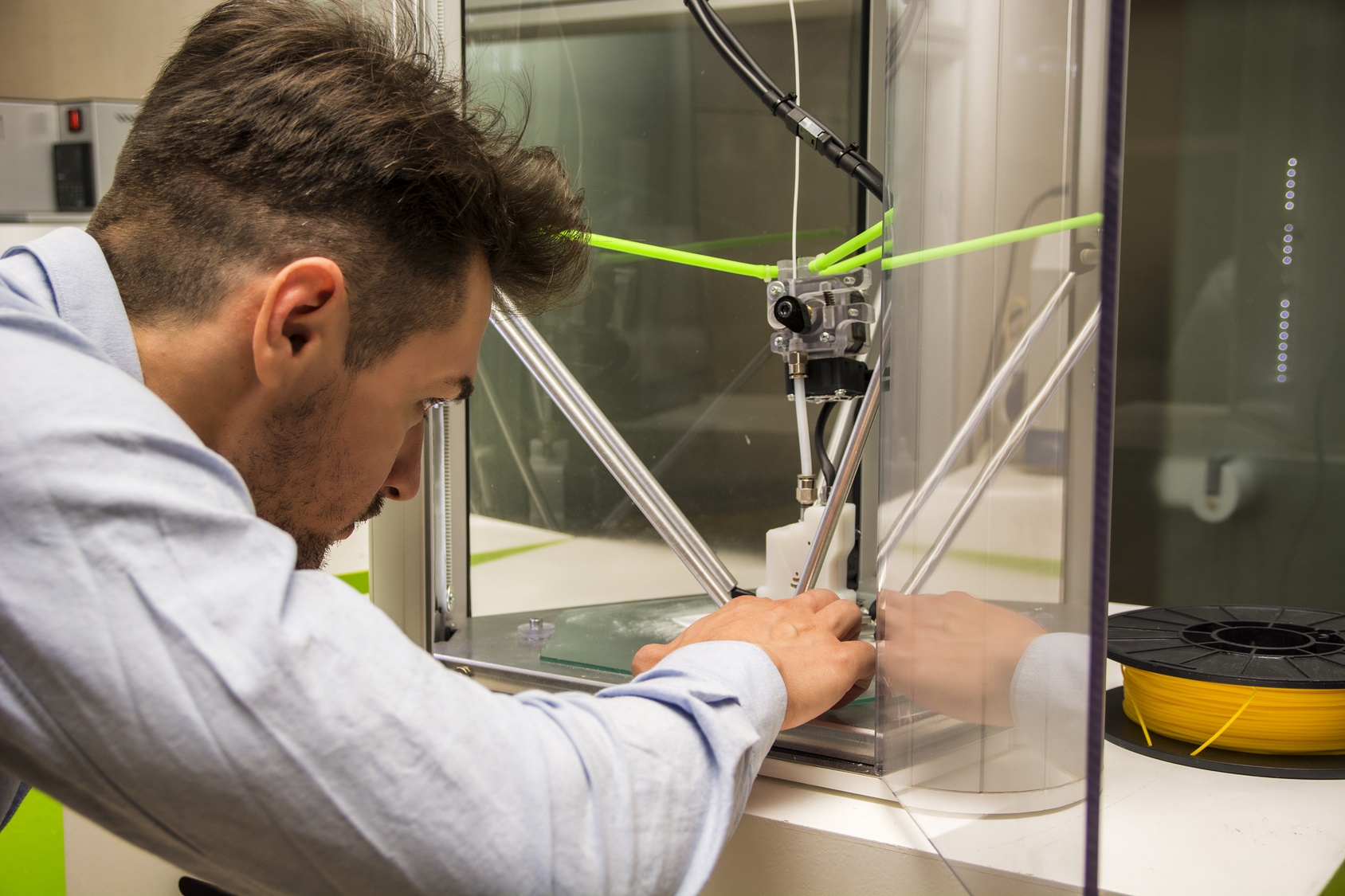

The Use Of 3D Printing In Manufacturing Now & In The Future

In recent years, 3D printing has become extremely useful in manufacturing—and, more specifically, in plastic injection molding. Injection molding companies often use a 3D printer to create a part from a model, drawing, or concept plastic part.

6 Types Of Injection Molding Technology

From advancements that have helped the industry for over 40 years to the latest cutting-edge innovations, there are a number of interesting plastic injection technologies out there that could be used to bring your prototype into production.

Meet Micron: An Innovative Injection Molding Company In Massachusetts

Hello! We’re Micron Products.

Founded in 1972, we are a full-service contract manufacturing and injection molding company based in Massachusetts. The shop we acquired at that time was founded in 1925, making us one of the oldest companies in the injection molding industry.