Growth is good—in fact, growth is necessary for survival. But just as the physical growth in humans comes with challenges, so does organizational growth. Unlike human growth, however, there are aspects of an organization’s growth that are within their control. One aspect of organizational growth that must be controlled is the quality of the organization’s processes and products to ensure that quality must never suffer at the expense of growth.

Applying QMS Fundamentals to Support Organizational Growth

How Automated Manufacturing Improves ROI

Contract manufacturing breeds innovation, but without the right experience to guide process engineering, it can be difficult to break out of established patterns. In this article we will compare the automated processes applied to two similar-yet-different products. While these items perform nearly identical functions, each has its own distinct assembly and packaging requirements. While many contract manufacturers would simply produce the parts simultaneously and add manual operations to each line, the team at Micron uncovered unique opportunities to increase efficiency and ROI by approaching each item as a unique part.

Micron Products is now Micron Solutions

Micron Products is expanding and changing its name to Micron Solutions to reflect an enhanced scope of services, including turnkey, complex assembly.

How to Know When Automated Manufacturing Is Right For You

Industrial technology has progressed at a breakneck pace recently, and the application of robotic technology and automation is a fundamental tool in modern manufacturing. According to the Boston Consulting Group, “combining advanced robotics with other technologies, process enhancements, and structural layout changes [in a manufacturing environment] can yield savings of up to 40%,” which presents considerable potential for manufacturing companies seeking to leverage the expertise of a skilled contract manufacturing partner.

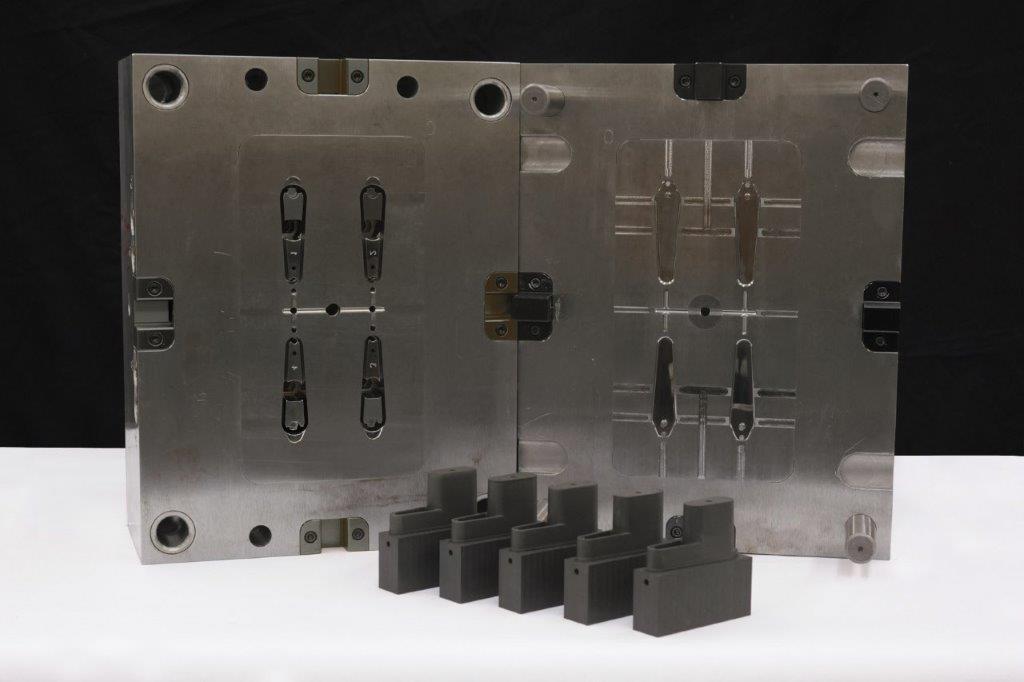

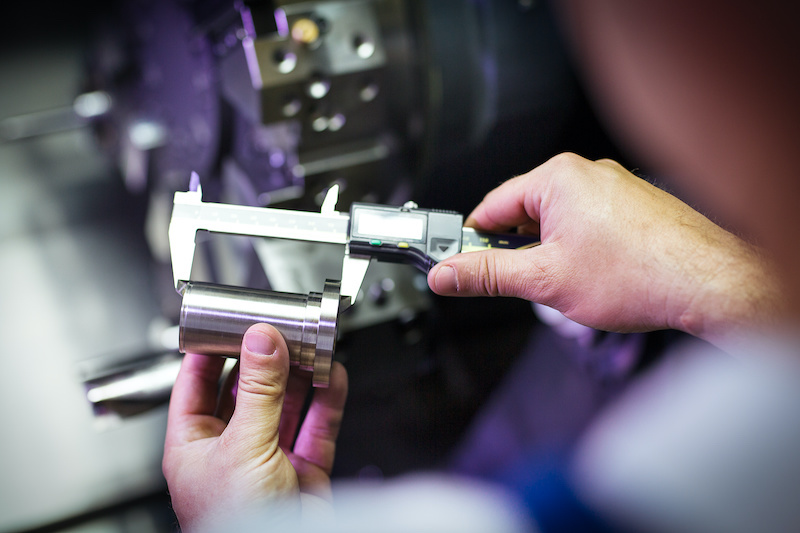

Tooling and Mold-Making at Micron

Mold making has a long history and it is no exception at Micron where we have mold makers with 35 to 45 years of experience under their belts. Our goal is to make quality, well-built molds for various industries and, with our experienced mold makers, we can achieve that.

The key to producing a high-quality mold is precise tolerances, maximum production performance and quality mold design. We are able to create these quality molds with the support of advanced machining equipment, a good quality team and the support of a qualified engineering department.

What Is Quality, Really?

There are almost as many definitions for Quality as there are quality practitioners. Some common ones include:

- Conforming to a quality standard

- Meeting customer specifications

- The standard of something as measured against other things of a similar kind

- Suitability for intended use

But what is Quality, really?

Why Leading Innovators of COVID-19 Home Testing Are Choosing Micron

The first half of 2020 has been, for many, a grueling gauntlet of disruptions to normal work and social behaviors. With the weather warming, people are demanding a quick and clear pathway to reopening schools, businesses, and social activities in a safe, reasonable manner. Public health officials have outlined several steps that must occur to safely resume normal activity, but one of the most prominent requirements consistently emphasized has been the need for widely-available, accurate, easy-to-use home testing for COVID-19. Calling upon years of experience manufacturing various components and consumables for medical testing kits, Micron is now working with some of the medical manufacturers leading the way for COVID-19 testing to become widely available in simple, single-use home test kits.

COVID-19 Notice

The world community faces unprecedented challenges in response to COVID-19, including increasing demand for essential medical devices throughout a period of global supply chain disruption.

Micron attends MEDICA Trade Fair in Dusseldorf Germany

11 Questions To Ask Before Picking A Plastic Mold Manufacturing Partner

When you’re getting ready to begin the injection molding process, the first choice you make—and one of the most crucial decisions—is which plastic mold manufacturing partner you’ll select. The partner you choose should, of course, deliver on all your mold requirements—but they should also prototype your part, help you with part design adjustments, warranty their work, and much more. And most importantly, the right partner will ensure you don’t end up with a useless mold that doesn’t produce quality parts—or, as we like to call a faulty mold—a boat anchor.