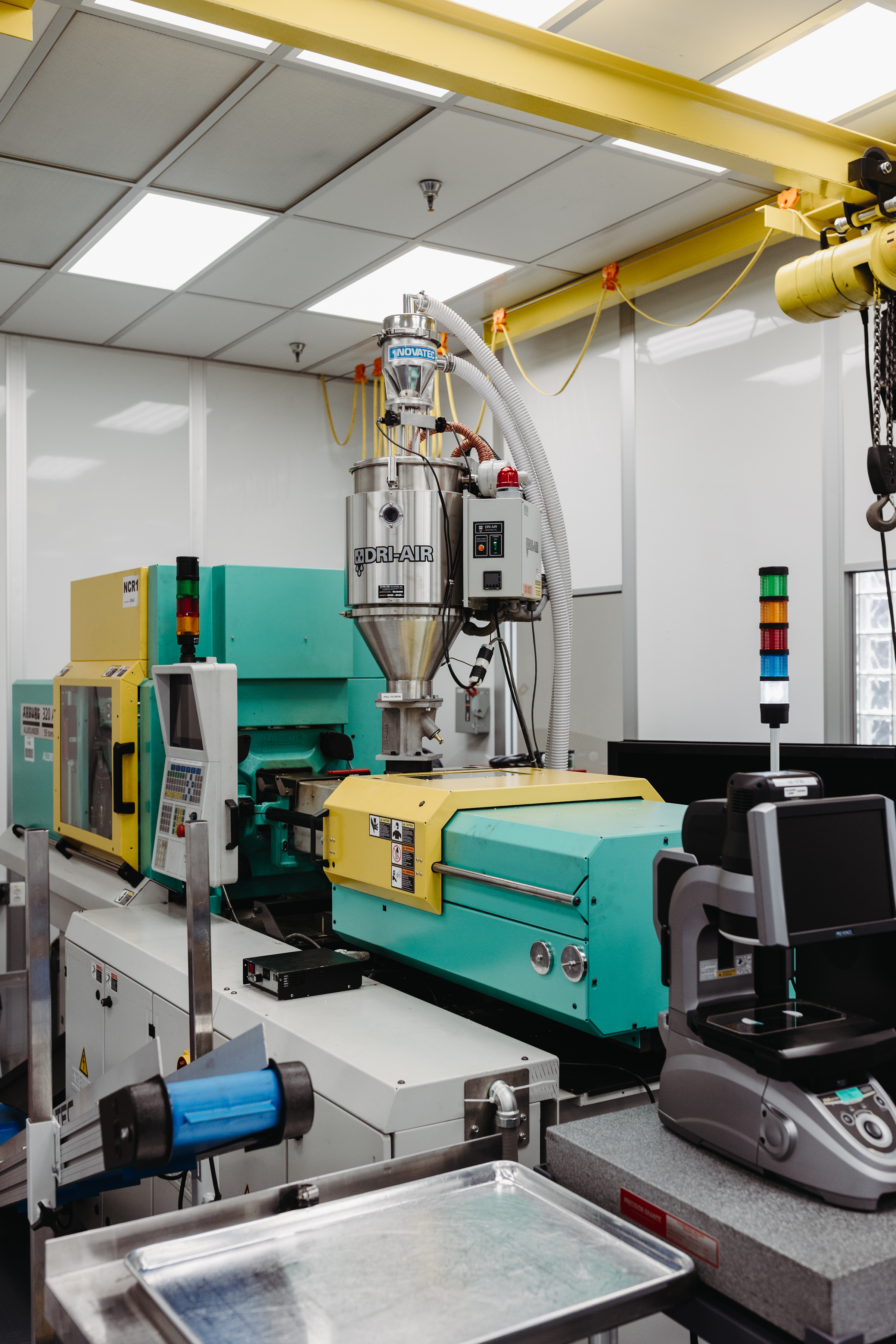

In the evolving landscape of manufacturing and technology, Micron Solutions stands out as a leading company dedicated to innovation and quality. With a distinctive approach of maintaining a 10:1 ratio of people to machines, we have carved a niche for ourselves in the competitive world of manufacturing. This balance between automation and human resources shows how committed we are to achieving the best results possible.

Human-Automation Collaboration in Manufacturing

Micron Solutions Returns from MEDICA 2023 with New MedTech Insights

MEDICA 2023 kicked off on November 13th in Düsseldorf, Germany, bringing together thousands of exhibitors and attendees from across the global medical technology landscape. As a leading manufacturer of cutting-edge medical devices, Micron Solutions is thrilled to have participated in this premier industry event.

Medical Design and Manufacturing (MD&M) West 2022 Event

Last week, part of Micron Solution’s upper management team attended the MD&M West convention in Anaheim, California. This event was a huge success with over 13,000 attendees all working toward the collective goal of pushing the boundaries of the medical industry.

Micron Solutions Wins 2021 'Manufacturer of the Year' Award

The team at Micron Solutions has always held themselves to the highest standards in the industry. This is something that we pride ourselves on as a core competency that defines the way in which we work on a day-to-day basis.

American Academy of Orthopaedic Surgeons (AAOS) Annual Meeting 2022

Thank you for joining us at this year’s American Academy of Orthopaedic Surgeons! We had a great time meeting so many new faces and discussing the latest developments in the industry.

We want to take a moment to thank the AAOS for their continued excellence in organizing such an important event.

Events like these allow for great minds to come together and work towards a collective goal of providing orthopaedic surgeons with the best tools and resources, allowing them to continue to provide top-quality care to their patients.

After a great conference, we at Micron Solutions can say that we have never been more proud to work with the AAOS as we strive to build a better world. We hope to see you all at next year’s event!

America COMPETES Act: How it Will Benefit Domestic Manufacturing

In February, the United States passed the ‘America COMPETES Act of 2022’ in the House of Representatives. This act is primarily focused on the development of research and innovation for the manufacturing sector.

Comparing Manufacturability of Orthopedic Implant Materials

Everything in manufacturing is intentional, from the machines utilized to the processes and operations in production— and material is no exception. Medical device producers around the world use a variety of materials, but metals, polymers, and ceramic are the most popular materials for orthopedic implant manufacturing. When manufacturers decide upon what type of implant they want to produce, they first assess its intended purpose and verify that it will meet the patient’s needs. After making this determination, material selection follows suit. The type of implant needed is always directly correlated with the material used.

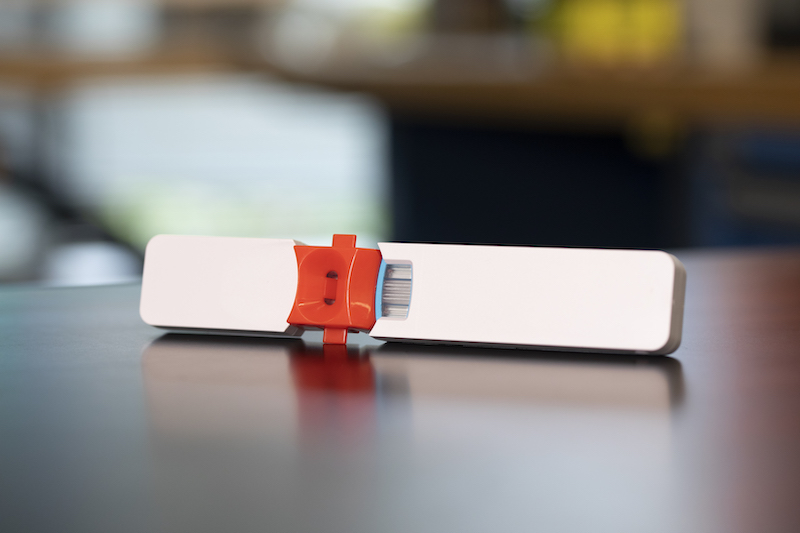

Manufacturing Efficiency Key In Expanding COVID-19 Test Kit Availability

With new strains introducing unique challenges in the fight against coronavirus, the demand for efficient and reliable COVID-19 test kits that can be used in the home has become increasingly amplified. Recently, medical device producers have reached out urgently to leading medical contract manufacturing companies for their help in overcoming many of the obstacles that were present in making these kits widely available. This is why, with decades of experience in comparable diagnostic test kit manufacturing, Micron was well prepared to rise to the challenge when a global medical equipment producer approached the team seeking the guidance and capabilities that needed to get their COVID-19 home test kit to market.

Reshoring: Reducing Costs and Returning Jobs to The United States

Reshoring is the act of bringing manufacturing jobs that had been previously exported to foreign countries back to the United States. On a national scale, returning jobs to the United States combats high unemployment, reduces trade and budget deficits, and bolsters the economy. Locally, manufacturing companies also benefit from reshoring by being an employment opportunity creator in their respective communities, but most notably benefits by reducing their products’ total cost and improving their balance sheets.

We Is Greater Than Me

We all have expressions we use that are representative of our cultures, our upbringing, our life experiences, or even just something we heard someone say that struck a chord within us. There are the famously inspirational sayings, like Vince Lombardi’s classic quote “Winners never quit and quitters never win," and the often over-used (but still very true), “There is no ‘I’ in ‘team’.” (Peter Drucker)