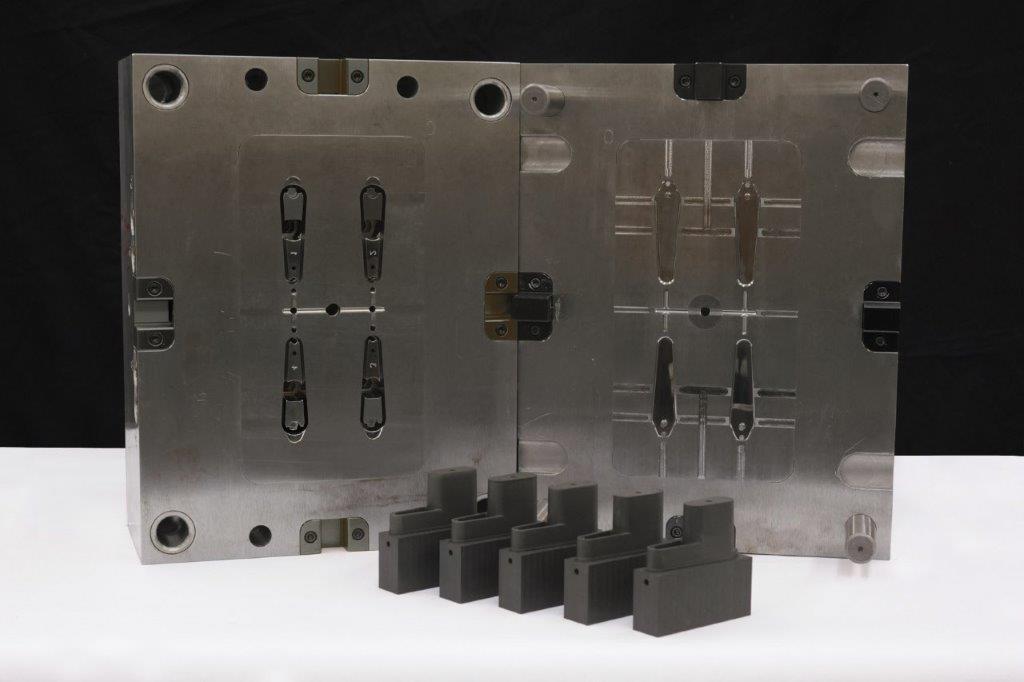

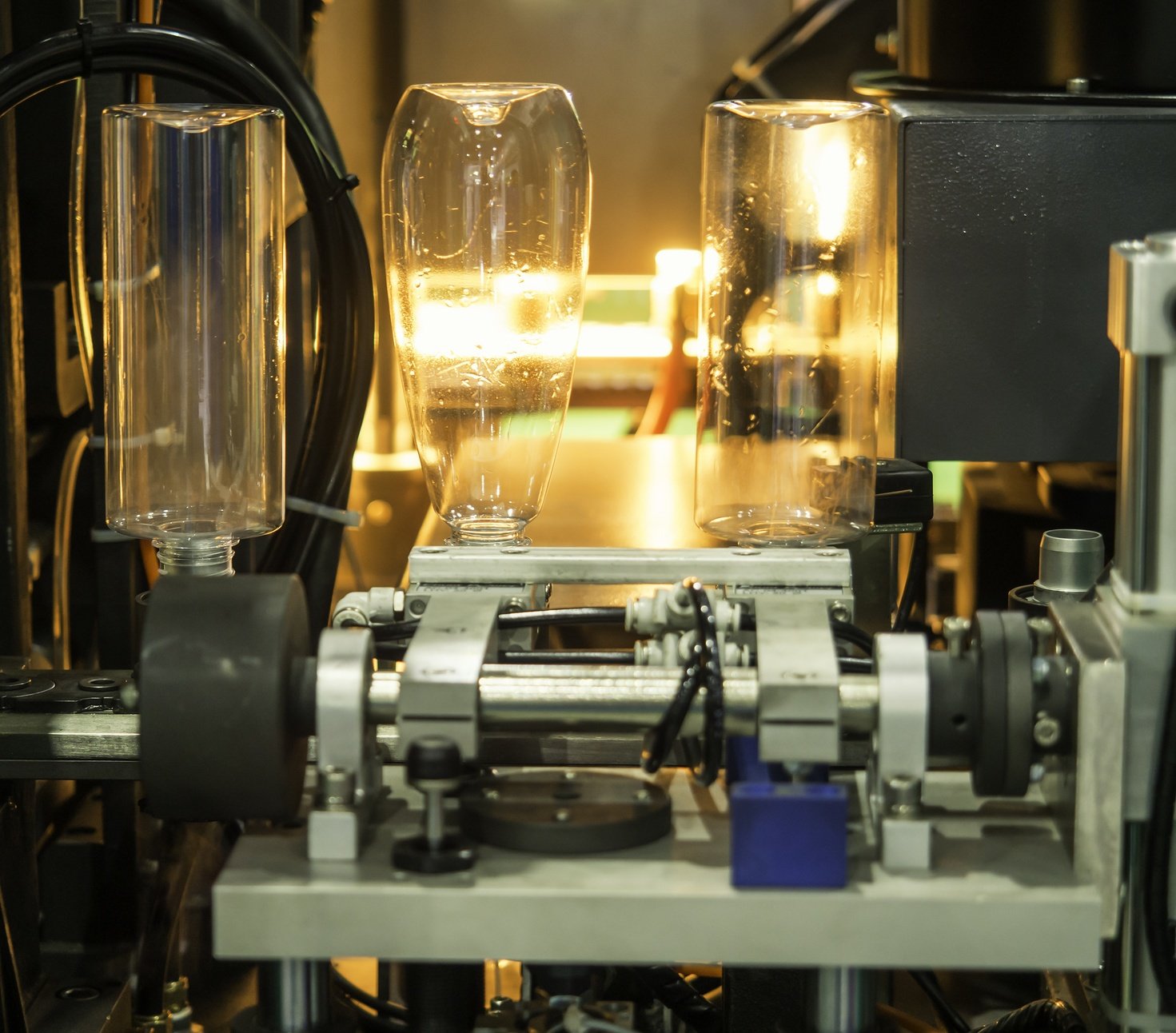

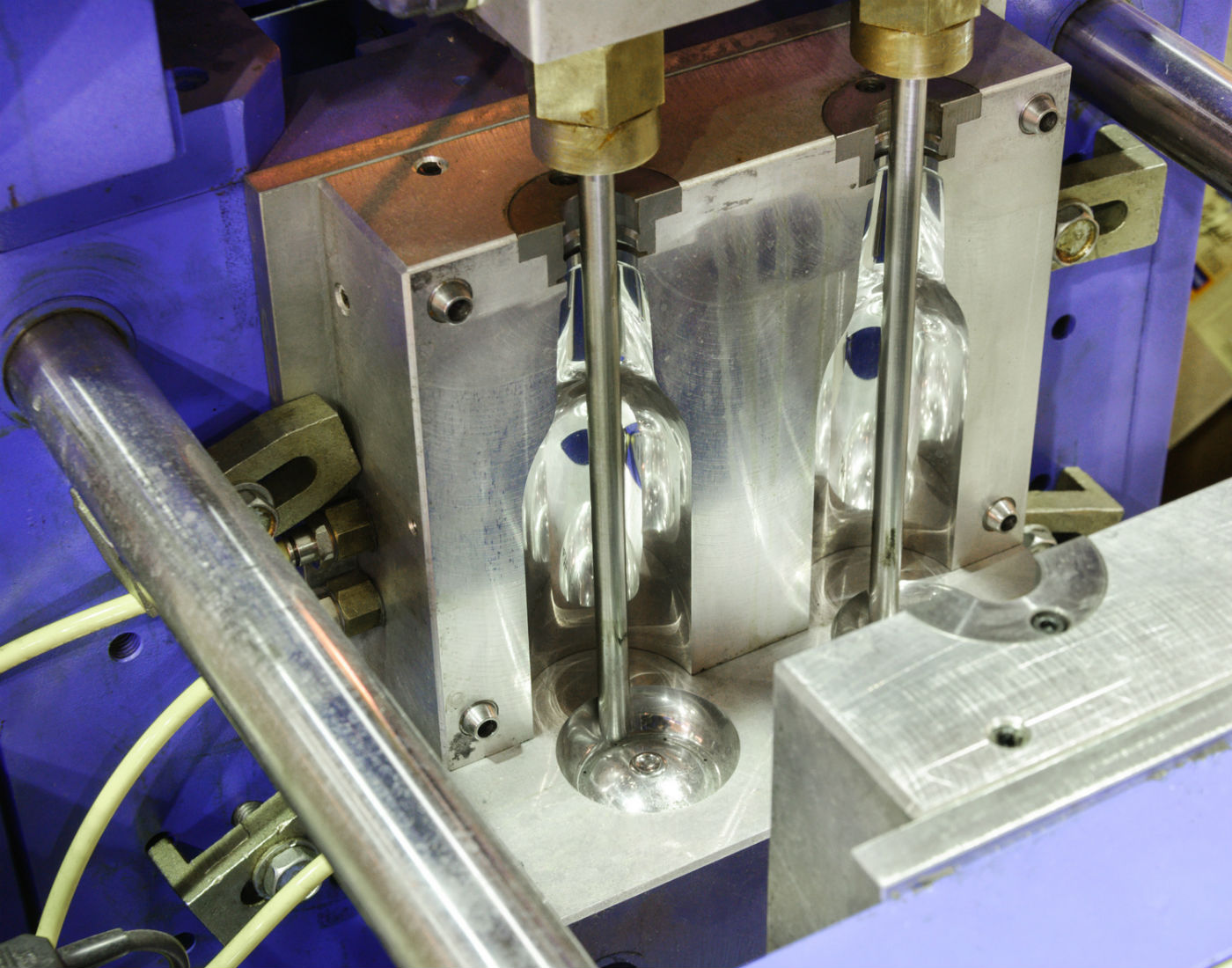

Mold making has a long history and it is no exception at Micron where we have mold makers with 35 to 45 years of experience under their belts. Our goal is to make quality, well-built molds for various industries and, with our experienced mold makers, we can achieve that.

The key to producing a high-quality mold is precise tolerances, maximum production performance and quality mold design. We are able to create these quality molds with the support of advanced machining equipment, a good quality team and the support of a qualified engineering department.